Spare Parts & Service Support

Maximising the performance of your food processing equipment

SF Engineering offers a range of service packages and service level agreements to maximising the performance of your food processing equipment.

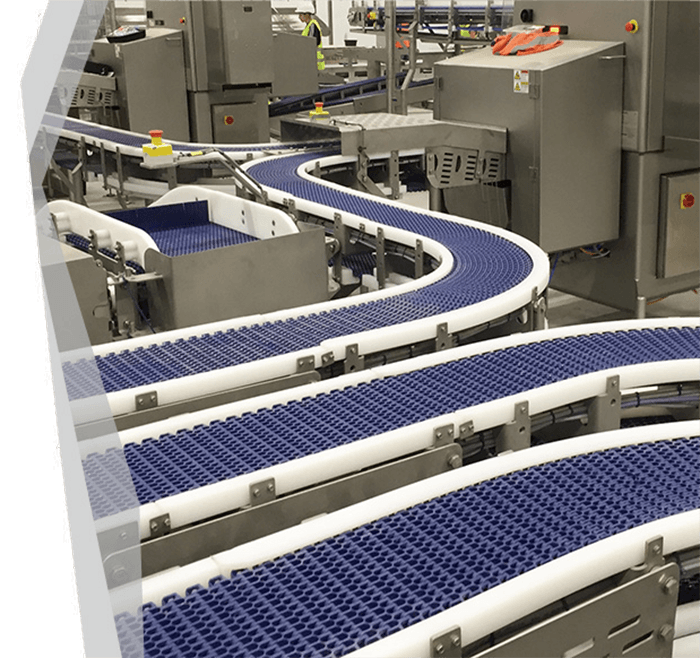

Keeping your production lines running at optimum performance is our main priority.

On-Site Service Support

Keeping your production lines running smoothly is our main priority

Our experienced and knowledgeable service technicians are on hand to solve any production challenges.

If any production problems cannot be diagnosed by our Service Team remotely via the web and phone, a site visit will take place.

We provide a range of Service Level Agreements, allowing you to specify how much or how little support you’d like to include and what kind of emergency cover you want us to provide.

This gives you peace of mind should something go wrong.

Spare Parts

Fast-tracked spare parts support to keep your production lines moving

Downtime can be extremely costly in the food industry. Our Spare Parts Team offer a quick and reliable service to keep your production lines moving at optimum performance.

Spare Parts Packages

We can customise a unique recommended spare-parts package for you, allowing you to carry out planned maintenance when required.

Alternatively, we can replace component parts quickly, as and when required. This enables you to choose the best option to suit your business, in the most cost-effective way.

Quality Guaranteed

We only supply the highest standards of genuine parts. This includes belts, motors, sprockets, bearings, electrical components and pneumatics from industry leading manufacturers such as Intralox, Lenze, SEW Eurodrive, Omron and Key Technology.

We are also an official provider of certified spare parts for our partner’s product range, including, Ishida, Marelec, Eagle, Ceia, Unikon and Roser.

Preventative Maintenance

Prevent problems before they happen and maximise your equipment’s performance

Preventative Maintenance is a programme that can help to keep consumers safe, reduce downtime, prevent systems damage and extend the life of your equipment.

If undertaken correctly, preventative maintenance can be a true cost-saver within food processing factories.

Our experienced service engineers provide pre-scheduled check-ups as well as detailed line and factory audits.

These inspections help maintenance technicians anticipate the appropriate time to change parts and can also help diagnose problems when they occur.

Remote Support

Secure, remote diagnostic support and programming for your machinery

Response time is a top priority for our Service Team.

Being able to remotely diagnose problematic machines, or assist with urgent programme changes is paramount if we want to respond quickly to our customer’s requirements.

The SF Remote Support Cloud allows our Service Team to react immediately to problems that arise.

By remotely dialling in to your machine, it not only saves you valuable time it also reduces service support costs.

Training

Get the best from your investment with our expert focused machine training

Our training packages will equip you with the knowledge and insight required to get the best from your investment and to understand the full capabilities of your new machinery.

Training ranges from technical equipment to capitalising on product yield and cleaning and maintenance of machinery. Our experts are on hand to train your production, maintenance and engineering staff.

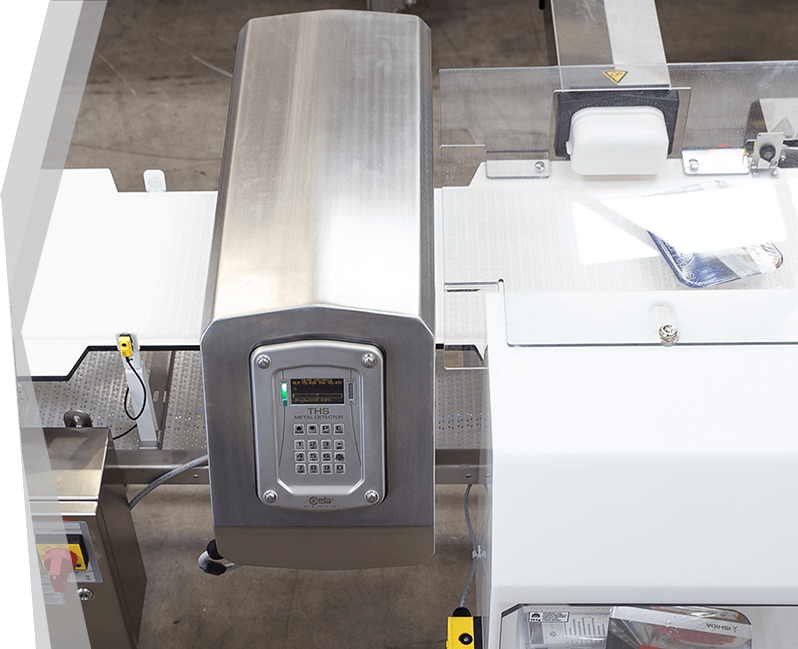

Calibration & Verification

Ensure your machinery is running at peak performance

Calibration is needed periodically, or after maintenance work, to ensure equipment is within specific parameters, critical for quantitative measurement. To safeguard the best results from your machine without incurring any measurement errors and product giveaway, regular calibration is required.

Our Service Team are also on hand to carry out verification checks to ensure the safe and correct operation of equipment and processes. These checks ensure you are getting the best return out of your investment and your lines continue to run at peak performance.