Fat Analysis

Real-time inspection and control of CL values in fresh, frozen, bulk or blended meat

Increasing Profits By Reducing Lean Give-Away

SF Fat Analysis solutions accurately calculate the fat percentage (CL) of meat, whether fresh, frozen, bulk, blended, or packed in cartons.

In addition to this, our systems are not affected by freeze/ thaw plant conditions, foil, metalised film, or meat conductivity.

Our ability to incorporate fat analysis technology into the unique processes of each butchery and processing plant sets us apart from similar systems.

Our in-depth knowledge of the red meat industry combined with our customisable solutions, ensures we offer our customers innovative systems with the best return on investment.

Intelligent customisation built into every solution

Instant CL calculation

Using Dexa x-ray technology the fat analysis machine is capable of inspecting 100% of throughput in real-time, providing in-depth reportable analysis within +/- 1CL. This non-invasive system provides lab accuracy at the speed of normal production.

Contamination Detection

The solution also works as a contaminant detector, alerting meat processors to a wide range of hazardous materials including metal, calcified bone, stone and glass. This technology works in freeze/ thaw plant conditions and is suitable for bulk products and even products packed in foil or cartons.

Customisable

Our fat analysis solutions are built in partnership with our customers. We specialise in incorporating fat analysis technology into the unique processes of each butchery and processing plant. This scalability is what sets us apart from similar systems and allows our customers to maximise the potential of this technology.

Real time monitoring

With real-time monitoring, meat processors can capitalise on the true value of their product. Whether the need is to reduce lean giveaway through trim management, to verify purchased meat was accurately priced with our pallet build solution, or to build accurate CL batches before mixing & blending.

What benefits you can expect from an SF fat analysis solution

Less lean giveaway – increasing profit through accurate CL monitoring

Safer product – with real-time contamination inspection & rejection

Improve process flow – inspection at real-time production speeds

Partnership support – to improve manufacturing processes and returns

Fat analysis solutions for butcheries and meat processors

Trim Management

More Information on the SF Trim Management System

The SF Trim Management System allows you to analyse accurately the CL ratio of red meat and manage your trim into batches of a pre-determined target fat percentage.

The benefits of this system

- Achieve real-time results.

- Less lean giveaway.

- Improved process flow.

- Foreign object contamination detection with automatic rejection.

- Live operator feedback with managerial reporting.

- Capitalise on the true value of your product.

How it works:

- Trim & flanks are transferred from the deboning line to the operator stations.

- In-feed operators visually grade the meat into portions of between 2.5kg-15kg, depending on product type.

- Once the correct weight is achieved, the hopper drops the product onto the fat analyser infeed belt.

- The fat analyser inspects 100% of the product within +/-1%CL in real-time. Providing lab accuracy at the speed of normal production.

- Built-in contamination detection will ensure hazardous batches are removed from the line before grading.

- The SF Grading Solution will gently grade trim to a target batch of a predetermined CL value.

- Remote and local management interface for controlled batch configurations.

- Grading station buffer hoppers will allow for continuous grading whilst boxes/crates are replaced.

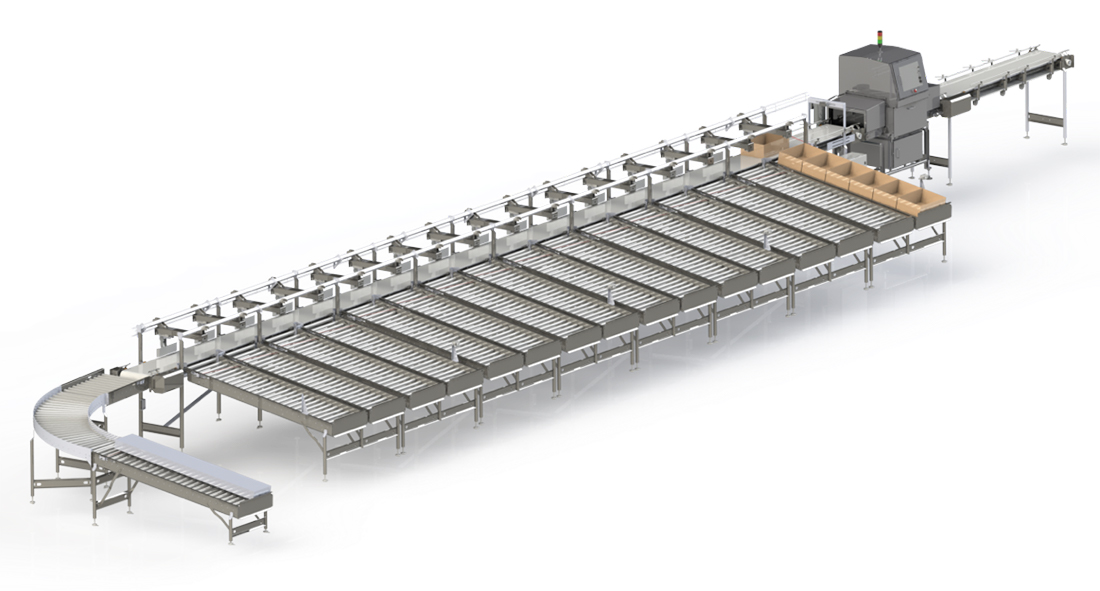

Pallet Build

More Information on the SF Pallet Build Solution

The SF Pallet Build Solution allows meat processors to inspect and grade incoming meat, ensuring purchased meat was accurately priced and allowing pre-production grading by %CL value before mincing and blending.

Benefits of this system:

- Verify purchased meat was accurately priced.

- Ensure the best possible batch combination is selected before recipe formulation.

- Optimise meat in-take labour requirements.

- Identify preferred suppliers.

- Foreign body detection & rejection.

- Access product tracking information quickly for supplier or customer feedback.

How it works:

- Boxed product travels on the in-feed conveyor, through the Fat Analyser.

- The Fat Analyser will inspect 100% of boxed product within +/-1%CL in real-time whilst simultaneously checking for foreign body contamination.

- Real-time inspection data can be transferred to an in-house software system. This information can verify supplier pricing was correct and initiate product tracking information.

- Boxes are graded into individual lanes according to the CL value of their contents.

- Rejected boxes continue to the reject station for further inspection.

Recipe Formulation

More Information on the SF Recipe Formulation System

The SF Recipe Formulation System is a turnkey solution that enables processors to formulate meat recipes containing one, two or more meat types whilst achieving a consistent and accurate CL value.

Benefits of this system:

- Lean meat giveaway reduction

- Achieve accurate blending targets and eliminate downgrading

- Eliminate any re-works of recipes

- Consistent product quality

- Additional yield from reclamation of blood

- Increase line efficiency

- Reduction in manual handling

- Identify preferred suppliers

- Foreign body detection

- Access product tracking information quickly for supplier or customer feedback

How it works:

- The product is dispensed from dolav to hopper conveyor and slowly fed onto the elevator belt.

- The product is conveyed to the operator loading area.

- The operator inspects and loads batches into the weigh hopper, following the exact instructions on his individual terminal.

- Weighed batches are fed through the Eagle Fat Analysing machine where CL is calculated and the product is inspected for contamination.

- Inspected batches are transferred to the grader which selects the appropriate exit to dispense the product.

- The software calculates the amount of additional fat required and prompts operator to add, ensuring an accurate CL value before mixing and blending.

- Optional blood reclamation pumps draw blood from drip trays to maximise yield.