Boost Efficiency During BBQ Season

From May through to September it’s no secret that consumers in Western Europe whole-heartedly invest in BBQ season. For food manufacturers, this window of opportunity is perfect to capitalise on new product lines to add extra value to raw material. However, this can often lead to a juggling act where manufacturers need to be increasingly flexible, firstly to ensure they remain labour efficient and secondly to continue achieving optimum yield.

As well as maintaining existing production lines, the requirement for shorter production runs of BBQ related product lines fluctuates greatly (depending on the all-important weather conditions). Without flexibility, producers are often faced with frequent product changeovers which take time to clean-down and set up set up.

Being able to quickly respond to short production runs doesn’t have to be time-consuming and expensive. Production lines that are multi-functional and machinery that can quickly adapt to rapid product changeovers ease the pressures of these seasonal peaks and troughs.

We have put together some examples of machinery and processing lines that can offer impressive efficiency, greater yield and save valuable set up times.

Portioning Equipment

The Marelec Portion Cutter is a high precision yet economic portion cutting machine suitable for fresh products such as fish fillets, whole fish, meat and poultry, offering fixed weight and fixed thickness portioning. The knife makes up to 1000 fixed weight cuts per minute, cutting to a level of accuracy and consistency no human could ever hope to achieve.

We have selected this piece of equipment due to it’s pre-programmed calibration which enables you to switch product setups in seconds making it a highly flexible portioning solution that always makes the right decision prior to cutting.

With increased yield, superior cutting speed and reduced labour requirements this portioner is ideal for BBQ products such as chicken strips, chicken chunks, beef and pork steaks as well as fish fillets.

Read more about our portion cutters.

Compact Grading

The Marelec M3 Compact Grader has been specially designed for the weighing and grading of small vulnerable products such as fish, poultry and meat. This efficient system is designed with infeed, weigher and outfeed in one simple and robust solution and the intelligent batching software can grade to size and number.

This grader is ideal for BBQ season as it can be used as a stand-alone solution for smaller production runs. With 100 pre-programmed adaptable product settings, it makes light work of batching and grading during BBQ season.

Find out more about our Compact Grading solutions.

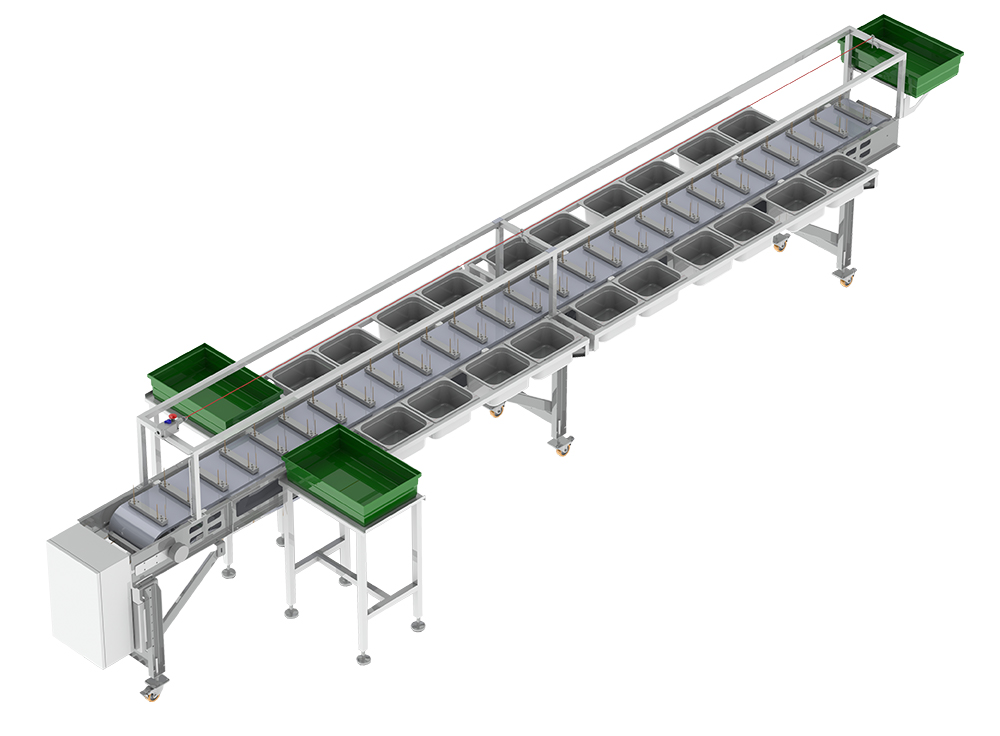

Kebab Line

The SF Kebab Assembly Line offers a lower cost solution compared to some fully automated machines, for the production of authentic homemade-looking kebabs.

Working to the pace line principle the SF Kebab Assembly Line allows managers to optimise labour. In addition, by removing the safety rail & skewer holders the line to be used as a standard conveyor offering flexibility during seasonal demand.

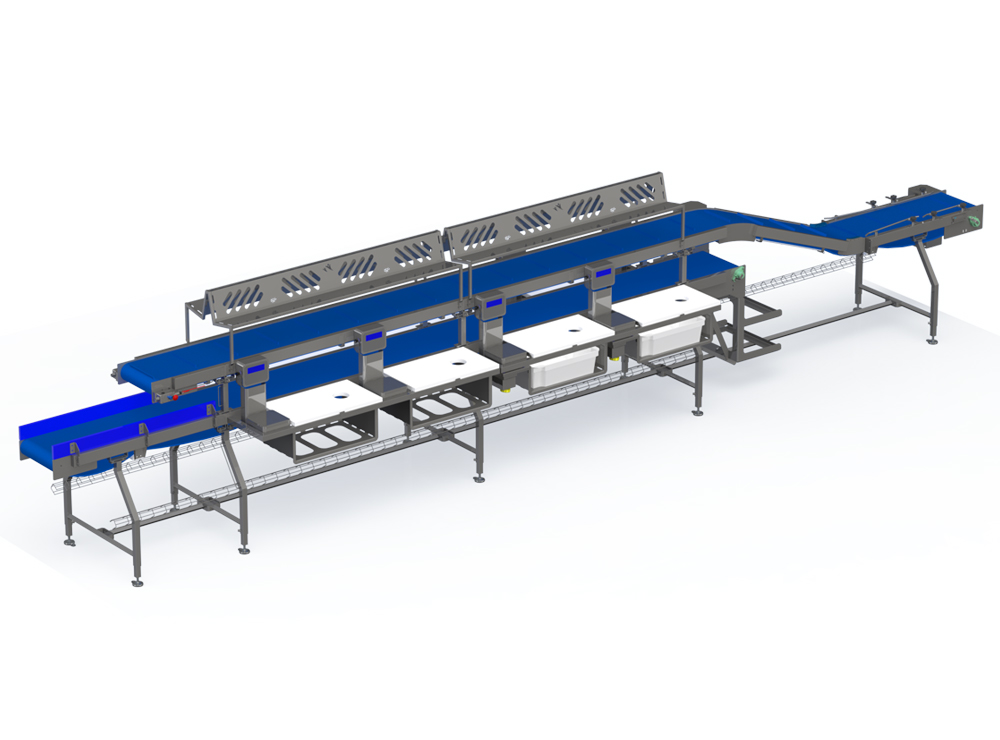

SF Packing & Prep Lines

The SF Tray Packing and Prep Line is an ergonomic solution for dressing and packing numerous added-value meat and poultry products into retail trays. It is versatile enough to be built into an existing production line or used as a stand-alone solution, making it ideal for seasonal product ranges or short production runs. Integrated scales can also be incorporated for products that need to be packed to weight or by count.

Find out more about our Packing and Handling solutions.

Eco Tray Wash

The ECO series is the perfect solution when moving from manual washing to automatic washing. It is both efficient in use of water and energy as well as achieving incredible labour saving costs.

Find out more about our Industrial Washing Systems.