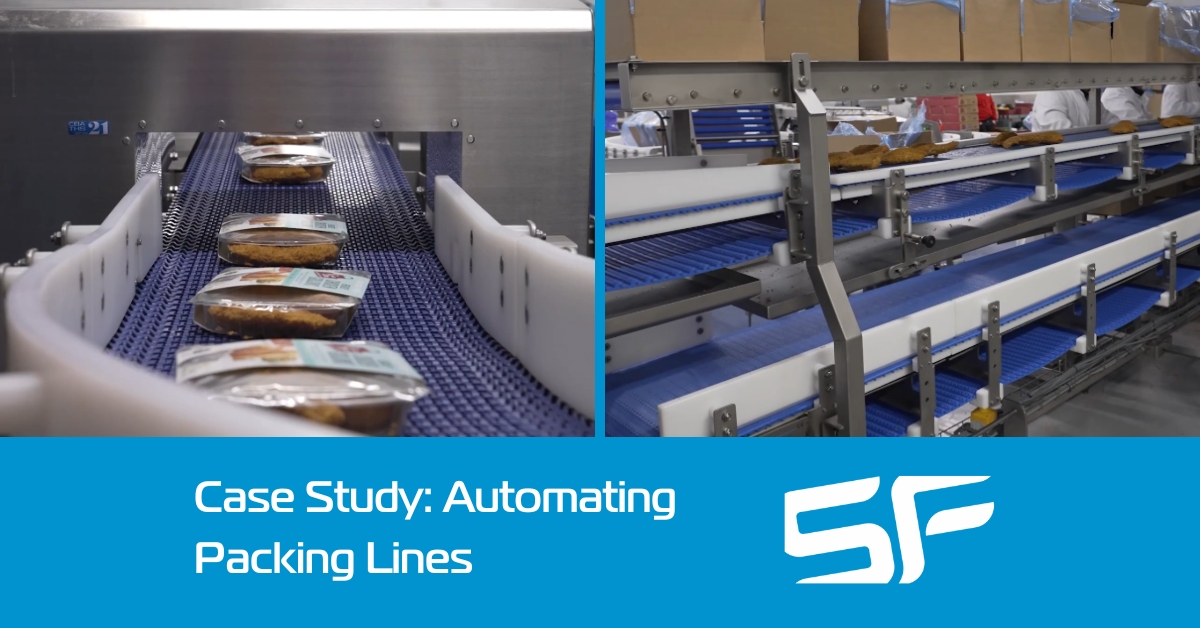

Case Study: Automating Packing Lines for Premium Chicken Product Manufacturer

Rosie & Jim is a leading manufacturer of high-quality gluten-free chicken products.

Its products are produced at the company’s manufacturing facility in Dublin, Ireland. Customer demand for Rosie & Jim’s products has been increasing in Ireland and further afield, resulting in additional pressures on packing processes. Many of the company’s packing requirements have also changed to meet customer requirements.

Rosie & Jim wanted to decongest the packing area, improve workflows, and minimise operator movement between lines. SF Engineering and Rosie & Jim have a long-standing relationship, where our team has delivered multiple production line solutions over many years. We were delighted to have been selected by the company to design and implement an automated packing line solution.

The project involved multiple elements, including three distinct packing lines, an empty carton feed system, and a separate product intake process.

This case study covers all elements of the project, including how we worked with the Rosie & Jim team to deliver an optimised solution. The new packing lines are now well-established, and they have delivered on the original objectives.

To find out more, download the Rosie & Jim case study now.