End-to-End Red Meat Process Improvements

Extracts taken from Steve Dowd, Regional Sales Manager, Eagle Product Inspection.

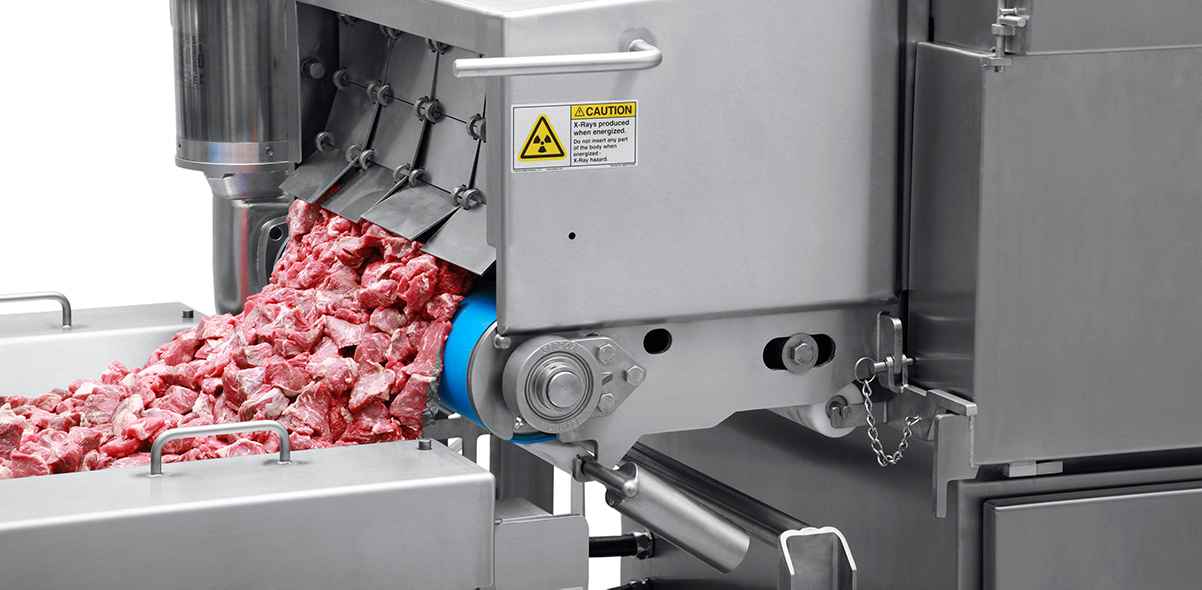

X-Ray Technology

Meat Food Processors are using advanced x-ray technology to inspect for contaminants at an early stage of the food production line and to ensure that products are meeting their requirements. Any discrepancies can be used to provide feedback for process improvements.

An example of this being applied can be seen in slaughterhouses and complete inspection systems. The products that are being shipped are free of contaminants and meet strict specifications set by customers or their own quality assurance specification. With slaughter houses, the processor wants to blend or fabricate a product efficiently. Inspection systems can slow the process down so that correction measures can be taken if the product is too lean to too fat. Advanced x-ray systems help slaughter houses label products based on the contents of the container and achieve correct specifications.

Benefits of Fat Analysis for Slaughterhouses

Fat analysis machines can inspect all products for foreign objects such as bones or metal without losing lean point analysis. The machines can provide data on inspected product from each supplier whilst helping meet correct recipe targets.

Benefits of Fat Analysis for Meat Processors

Regular improvements in FA3 technology have improved detection capability, blending and recipe management. Eagle’s software SimulTask™ PRO (screen diagnostics, advanced image analysis and quality assurance traceability) and TraceServer™ (real-time monitoring, storage of information images and reports) is continually updated and customised for each operator.

Customisable detection systems demonstrate the efficiency of the meat industry and provide actionable information. For example, if a customer has a carton line and wants to inspect bone-in or boneless beef products, barcoded readers switch between 1,500 different product codes enabling the user to determine if a scanned product has a contaminant, a certain lean point or mass and whether or not it is correctly marked as bone-in or boneless. If a carton is rejected, information is sent to the reject station, where the reject operator scans the carton and resolves the issue. If too many rejects are occurring, the operations lead identifies the root cause and addresses the process or supply chain issue. Reports are then sent about each product code, reject information and production efficiency.