Keeping pace with accelerating retail-focused demand

Are your production lines running at optimum performance and returning the best product yield or are incorrect weighments causing product waste?

Since the pandemic began, there has been a seismic shift in demand for retail-focused products. With the eating out of home sector succumbing to international lockdown restrictions, food service demand has taken a significant downturn. Where sales have declined for these food producers, innovative thinking and fast action to restructure existing processes has been essential. For food processors supplying to the retail sector, the vast increase in demand, coupled with preserving the health and safety of staff has brought its own unique challenges.

Throughout this time we have been supporting numerous customers from all industry sectors with these exact challenges. To restrict contact between line operatives, we have supplied and installed PPE screens on new and existing lines. Production line upgrades have helped our customers increase their throughput levels to fulfil increasing demand. While remote service support devices have been retro fitted to assist with diagnostics and line improvements.

Improving the efficiency of processing lines

With the strain on food producers not showing any signs of lessening in the near future, the emphasis remains on improving the efficiency of processing lines to ease the pressure of retail fulfilment. When it comes to offering optimal production speeds, accuracy and efficiency, it’s hard to beat a fully integrated solution from a single source supplier. With each piece of machinery in perfect alignment for high-speed optimisation, production volumes can be met with ease.

Our alignment with leading global equipment suppliers such as Ishida, allows us to incorporate world-class food production line solutions that are specifically focused on precision, yield and quality control under one brand. This means that you receive seamless supply, integration and support from a single source supplier.

Invented by Ishida in 1972 and now with more than 51,000 machines installed around the world, The Multihead Weigher is pivotal to the improvement of efficiency and consistency on a retail focused production line. Ishida has offered virtually every known multihead application solution, so, if your product are free flowing or sticky, different bulk densities or varied product sizes, or even different target weights, there is a Multihead Weigher solution for you.

Elimination of product waste

Product waste is virtually eliminated because of the speed of Ishida’s unique combination calculation hardware and software. It is so fast, that it can put together not one but three different combinations for each weighment and double check the results. Incorrect weighments and wasted, dumped product is a thing of the past.

We understand that one solution does not fit all production processes. Your demands are unique, so with that in mind, we design and build solutions to specifically meet every one of them.

Improved yield

Small fluctuations in giveaway can have a significant impact on your revenue. You need a solution which focuses on eliminating guesswork and maximising your yield, resulting in higher profits throughout your business

Reduced labour

High-quality products at increased production speeds with less personnel is possible to achieve. In fact, we focus on reducing your dependency on highly skilled labour in all of our standard equipment and full turnkey solutions

Superior pack presentation

Control, accuracy and speed are key to achieving superior pack presentation and increased shelf life of your product. Our range of world-class leading weighing, handling and packing and sealing technology will ensure your product is presented at its best as it leaves your processing facility.

We’re here to support your retail-focused processing lines

SF are here to help you assess your processing needs and to optimise your production process. Our planning, design and project management experts will provide unlimited assistance from consultation, right through manufacture, installation and commissioning. Our teams are very familiar with the demanding conditions that arise across the food industry and have gained a vast knowledge of solving complex challenges on a daily basis.

Contact our team to discuss your production challenges or to enquire about any of these products.

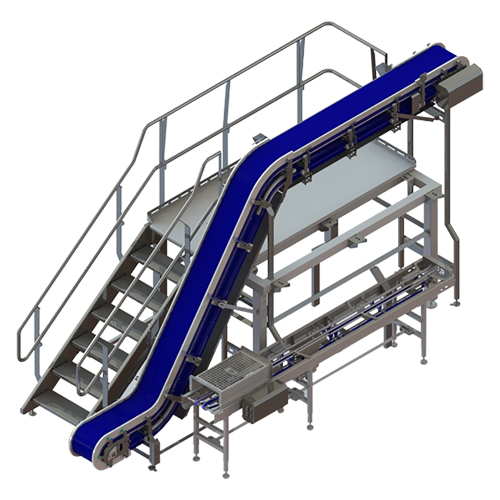

Conveyors & Platforms

Multihead Weighers

Checkweighers

Weigh Price Labellers

Tray Sealers & Denesters

Handling & Packing

Metal Detectors

X-ray Inspection

Lifting & Tipping

Industrial Washers & Dryers