Manufacturing Food Processing Equipment to Strict EHEDG Standards

All the food processing equipment that we design and manufacture at SF Engineering meets and often exceeds existing regulatory requirements in Europe, the UK, the US, and other jurisdictions around the world. We are now seeing a growing number of customers requesting food processing equipment that meets the safety and hygiene standards set by other organisations, including the EHEDG.

The EHEDG (European Hygienic Engineering and Design Group) has developed hygiene and food safety standards that often exceed those required by regulators. The organisation comprises members from across the food manufacturing sector and while it is European based, it has a global outlook. The aim of EHEDG in creating its standards and guidance is to improve food safety and quality.

EHEDG Standards

EHEDG’s standards are outlined in an inventory of over 50 documents that focus on 10 areas of food production:

- General principles, materials, and surfaces

- Test methods

- Factory design, including the design of utility systems

- Closed equipment for liquid food

- Closed equipment for dry particulate materials

- Open equipment

- Packaging machinery, including filling machinery

- Heat treatment

- Cleaning and validation

- Training material

Some examples of the standards and requirements in EHEDG’s guidance include:

- Materials of construction – materials that come into contact with products must be inert to the product as well as cleaning materials and sanitisers. Materials used to manufacture food processing equipment must also be corrosion-resistant, easily cleaned, and mechanically stable.

- Surface roughness – the focus with surface roughness is cleanability, so surfaces must have a maximum roughness of Ra = 0.8 µm. Sharp corners, crevices, shadow zones, and protrusions are not allowed.

- Screw threads – should be avoided.

- Drainability – equipment and process lines should be self-drainable.

- Top rims – to make top rims easy to clean, they should be rounded and sloped.

EHEDG Expertise at SF Engineering

Our engineers have experience developing food processing lines and solutions that meet strict EHEDG standards. Some examples of the features we include in EDEGH-compliant equipment include:

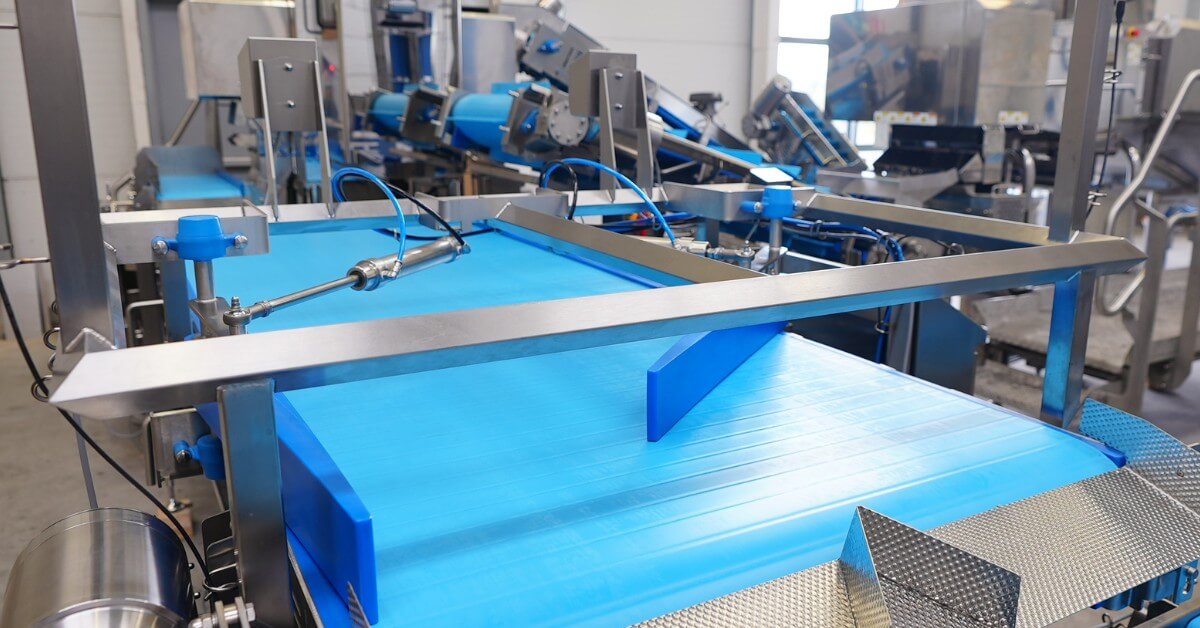

Angled Surfaces

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Equipment frames are diamond-shaped rather than square to eliminate flat surfaces, while other surfaces are also designed with angles.

Plastic Elements

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Plastic bearings and other plastic elements are coloured blue rather than the standard white to make the plastic easier to identify if it gets into food product.

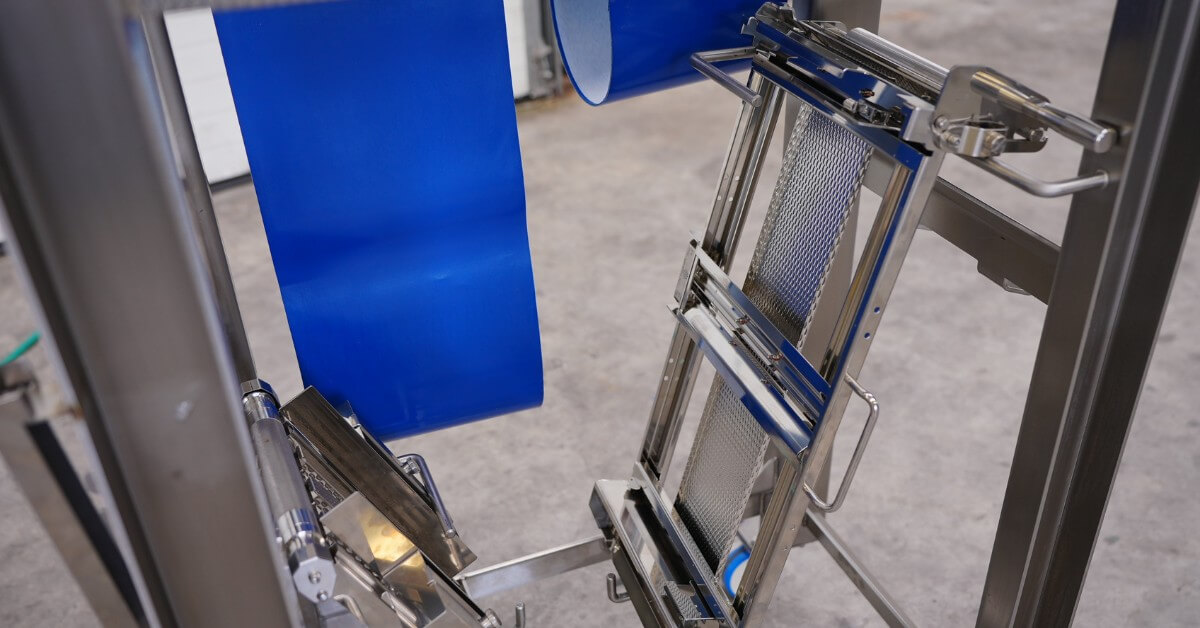

Open Design

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

All elements have an open design to enhance cleanability.

Pipework

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

All pipework is exposed to make it easier to clean. Furthermore, horizontal pipework sits at an angle to ensure water drains to the lowest point. This ensures there is no water left in the system, especially in situations where the equipment is not in use for a period of time.

Stainless Steel Gear Motors

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Our stainless-steel gear motors are manufactured to IP69K standards, so they don’t need protective covers and can be washed down directly.

No Exposed Threads

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Elements that commonly have exposed threads are replaced with fully encapsulated designs. This eliminates the exposed threads to make them significantly easier to clean.

Removable Parts

EHEDG-spec equipment is designed with removable parts. All removable parts have cleaning brackets on the frame where they can be attached for cleaning.

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Built-In Belt Lifters

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

All conveyors have built-in belt lifters to make them easier to clean.

Surface Finish

Note: all photos taken are of a food production line going through pre-delivery inspection processes at SF Engineering’s manufacturing facility.

Food production equipment commonly has a shot blast finish that is very hygienic and produces a highly uniform finish. However, as EHEDG standards require a maximum surface roughness of Ra = 0.8 µm, we use a polished finish for EHEDG-spec equipment.

Support for Your Project

If you are looking for food production lines or equipment manufactured to EHEDG standards and specifications, get in touch with us at SF Engineering. Our engineers have detailed knowledge of EHEDG requirements in addition to our decades of experience in the food manufacturing equipment industry. Contact us today to discuss your project.