Metal Detectors

Protecting your customers and your brand

Exceeding the strictest quality control standards

We are proud to partner with the world-leading suppliers in order to offer our customers the best in-class solutions. Our partnership with Ceia is no exception.

Ceia Metal Detectors detect metal contaminants accidentally present in food production with levels of sensitivity, immunity to interference and response speeds exceeding the strictest Quality Control Standards.

They help minimise operator intervention and line stoppages with incorporated advanced features such as the Auto-learn system, self-calibration, and continuous auto-test functions.

Benefits of a Ceia metal detector

Unique detection capability of magnetic, non-magnetic including stainless steel

Extremely high adaptability to compensate for product effect

AISI 316L stainless steel construction to IP66 and IP69K protection levels

Robust design and durable construction with food compatible plastic parts

Automatic learning & tracking of product effect

High immunity to environmental interference

Between 250 and 500 product data memories

Reduced operator intervention & line stoppages

Fully HACCP and GMP compliant

Supermarket specifications compliant

Multiple ejection systems available

1,000 storable events

Unparalleled inspection performance

Ceia Metal Detection Systems offer detection, construction quality and reliability characteristics that make them the most suitable and effective solution to automate elimination of metal contaminants.

If you need further assistance, please contact our team.

Metal Detection - Head Only

More Information on Metal Detection - Head Only

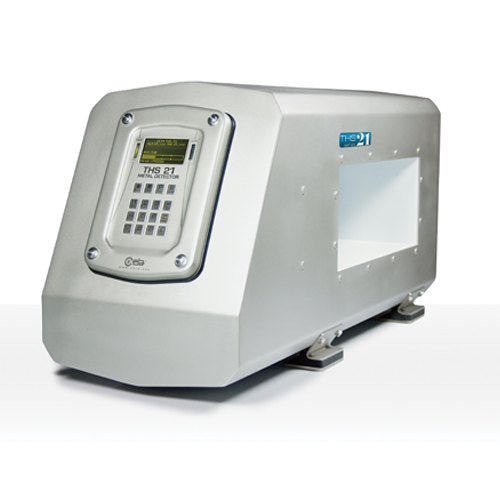

THS/MS21 THS/21 – Multi-Spectrum

Offering the highest level of metal detection available. These metal detectors are perfect for products, such as cheese, fresh meat, and poultry.

THS/21E-3F THS/21E – Multi-Frequency

An entry-level CEIA metal detector with single- and multi-frequency technology is ideal for processors with all manner of food products.

THS/G21 Series – For free-falling product

These highly sensitive vertical metal detectors inspect all manner of snack foods, powders, liquids and granules that are transported in gravity-fed tubes.

Contact SF Engineering Ireland for more information.

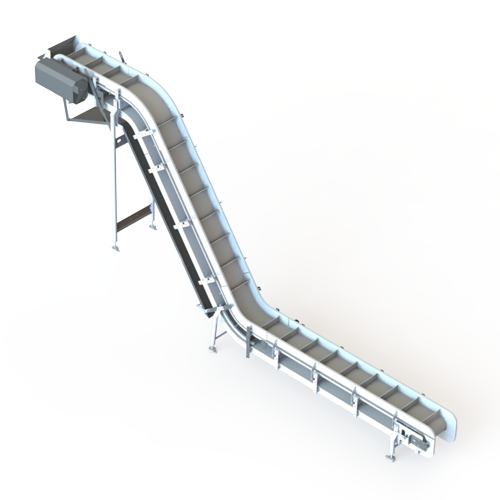

Metal Detection - Conveyors

More Information on Metal Detection - Conveyors

Supplied as a standalone unit that can easily be incorporated into your existing production line. The Ceia’s conveyor inspection systems detect and eject magnetic, non-magnetic and stainless steel metal contaminants in food products.

Designed with a choice of belt configurations which are integrated with THS metal detectors and ejection systems, each system is equipped with digital control of the belt speed and ejection of non-conforming products.

Suitable for a range of ready meals, fresh and frozen products, packaged and trayed goods.

THS/FBB – Flat Belt configuration

THS/MBB – Modular conveyor belt configuration

THS/MBR – Modular retractable conveyor belt configuration

THS/RB – Round conveyor belt configuration

Contact SF Engineering Ireland for more information.

Metal Detection - Combination with Checkweigher

More Information on Metal Detection - Combination with Checkweigher

When used in combination, a CEIA metal detector and an Ishida checkweigher enable accurate high-speed package inspection of all ferrous and non-ferrous metal contaminants. This includes stainless steel and verification of current product weight or count.

Available with a variety of models, you can create a customized inspection system to meet your production needs. Ideal for packaged products, snack foods, ready and prepared meals, salads, meat, fish and poultry.

Contact SF Engineering Ireland for more information.

Metal Detection - Ferrous in Foil

More Information on Metal Detection - Ferrous in Foil

The THS/MN21 model is a highly reliable detector of ferrous and magnetic metal contamination for products in aluminum trays, foil, and foil-wrapped bags. Offering maximum-sensitivity at both high and low transit speeds.

Contact SF Engineering Ireland for more information.

Metal Detection - Pipeline

More Information on Metal Detection - Pipeline

Ceia’s pipeline metal detector range is specifically designed for detecting metal contamination in products transported by a pipeline. They feature a fast reject valve drive response to reject the contaminant without slowing down the product flow. Ideal for the production of cheese, preserves, soup, meat, poultry, and seafood.

THS/PL21 series

An integrated pass-through system for liquid and viscous products

THS/PLV21 series

An integrated pass-through system with ejection valve integrated system for liquid and viscous products

THS/PLVM21 series

An integrated pass-through system with ejection valve integrated system for applications on meat vacuum filler machines

Contact SF Engineering Ireland for more information.

Metal Detection - Free Falling Products

More Information on Metal Detection - Free Falling Products

THS/FFV21 series

These integrated metal detectors are designed for the inspection of free-falling granular and powder products as well as loose materials transported in gravity-fed tubes.

Contact SF Engineering Ireland for more information.

Which metal detector is right for you?

Single-Frequency

Ideal for basic product inspection due to its limited abilities to work with different products, to optimise for varying conditions of temperature, water content and packaging types.

Multi-Frequency

These metal detectors operate with multiple frequencies (one frequency at a time) capable of detecting a variety of products that have a range of characteristics.

Multi-Spectrum

For the ultimate performance, these metal detectors operate over an entire spectrum of frequencies simultaneously. Resulting in optimum sensitivity and accurate compensation of product effect.