Protect Your Food Brand

Using technology to protect your brand in food processing

As a food processor working to the highest standards, you know the damage food contamination can do to both your brand and your customers. It’s crucial you put the right procedures in place as the consequences can be very serious and are usually easily preventable. From managing risk to improving quality, there are many good reasons to apply metal detection and x-ray technology in your facility. When it comes to product safety, quality control and processing management, at SF, we supply only the best inspection systems. By installing CEIA metal detectors, Ishida checkweighers, and Ishida X-ray systems, we’re working with you to minimise the risk of food contamination. Our knowledge of the industry means you get the benefit of many successful implementations and a solid track record. Your brand and reputation is too important so you should only work with suppliers of the highest level to ensure maximum protection.

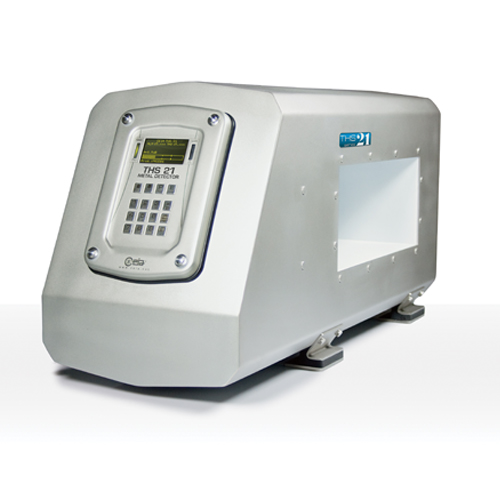

CEIA is much more than a metal detector

As the world’s largest manufacturer of metal detectors, CEIA has developed multi-spectrum technology that is not available in any other metal detector brands. Not only that but CEIA MS21 detectors accurately differentiate between product effect and metal contaminants with no need to reduce sensitivity. CEIA has everything you would expect from a leading solution. Its Global Auto-Learn system can select and display the optimal sensitivity setting to completely eliminate guesswork and human error. Already-stored detection settings will enable a speedier process and a more accurate one too. With the ability to hold hundreds of products in system memory, changeovers are smooth and hassle-free.

Ishida has the x-factor

And when it comes to X-ray systems, Ishida combines the capabilities of a checkweigher and metal detector with the ability to detect tiny, non-metallic contaminants, such as bone, glass, shell and plastic. Ishida’s system can also verify weight and identify missing or defective products. Risk management in food contamination is an issue for processors of all sizes and SF can supply X-ray inspection for every application and budget. Ishida’s solutions really tick all the right boxes. With a user-friendly, easy-to-read 15” touch screen control panel, it’s ideal for the busy processing facility. It’s very easy to clean and its stainless steel construction conforms to HACCP. An open framework ensures easy access for sanitation. And there are no tools required to remove conveyor for cleaning. It prioritises flexible data management and sensitivity settings can be confirmed without stopping the X-ray process.

To put it simply, CEIA and Ishida are the premium products in the market and the best at what they do. At SF Engineering, our focus has always been providing the best solution for your needs and we do this by partnering with industry specialists. We’ll work hard to provide you with only the best brands, helping you to protect yours.