Quick Guide: Choosing the Right Meat Portion Cutter

Getting the right portion cutter for your meat processing facility will help you meet the exacting needs of your customers. You’ll also be in a better position to take advantage of new opportunities in the market, as well as improving the efficiency of your meat processing lines. The latter covers everything from achieving a target of zero waste to maximising product yields.

The objectives when choosing a portion cutter are typically to automate, simplify, speed up, and improve the accuracy of meat portioning. How do you do this, however, and how do you make sure you get the right meat portion cutter for your requirements.

One hugely positive factor on your side is that portion cutter technologies have advanced significantly over recent years. With expert advice and a solution-driven approach, you will get rapid a return on investment with a portion cutter that can meet your needs today and into the future.

Intelligent Portion Cutting

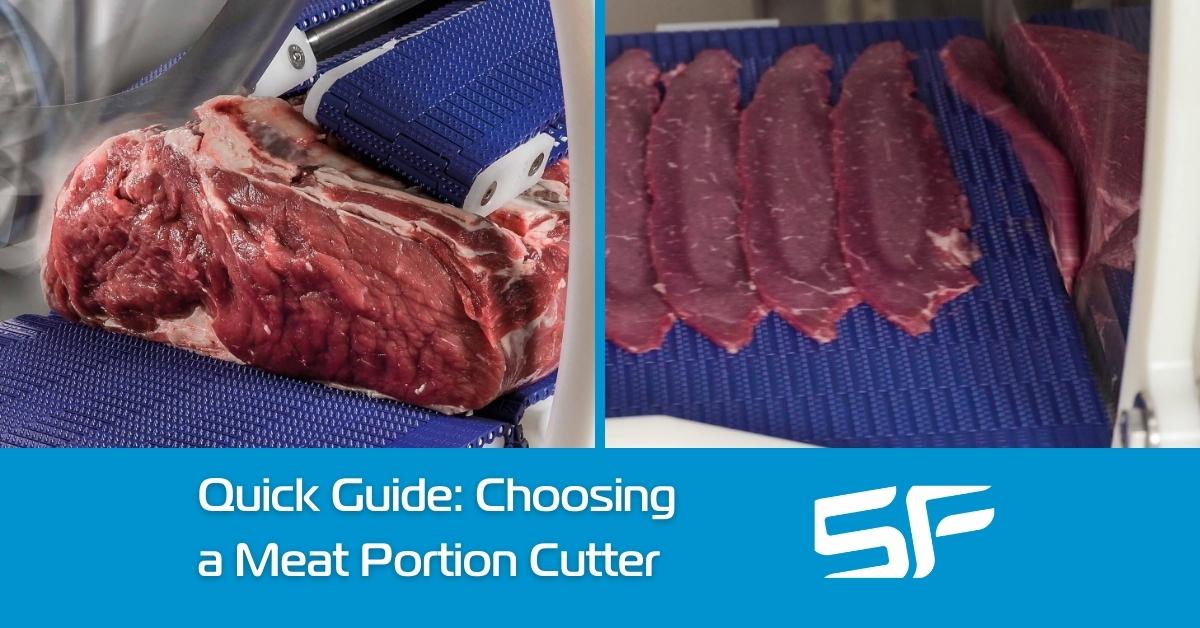

Intelligent portion cutting machines scan the product before it is cut. Laser cameras are used for the scanning process to ensure the highest levels of accuracy, with the machine then programmed to produce the required cut and target weight.

By way of example, the Marelec portion cutters that we supply on our meat production line solutions feature three cameras that scan the product from the top and sides

As intelligent portion cutting machines produce precise cuts, you get meat portions that are the right thickness and weight for your requirements, while also optimising yield. Waste is reduced to zero.

Customer Considerations

What are the requirements of your customer? The answer to this question is crucial in determining the right portion cutter for your requirements, as there are multiple options available. Intelligent portion cutting machines, like those manufactured by Marelec, will produce fixed-weight portions. However, this is only the start of the list of capabilities and features included in advanced portion cutting solutions.

We can look at the appearance of the product as an example. Does your customer want uniform portions? If so, you will need a portion cutter that cuts the meat to the required shape, weight, and/or thickness. However, a different range of machines might be more suitable if your customer is happy with variable and more naturally shaped cuts.

Again, we can use Marelec portion cutters as an example. The portion cutters in its range can cut to a fixed weight, fixed thickness, or a combination of weight and thickness variables to ensure maximum yields from your meat primals.

Portion thickness is another example of a customer requirement that you will need to consider, as all portion cutters have minimum and maximum cutting thicknesses. This needs to be taken into account, particularly if you need very thin portions or very thick cuts, such as roast cuts.

Operational Considerations

There are then several operational considerations that will help determine the best portion cutter for your needs. This includes assessing the yield optimisation capabilities of the machine, as it’s not just about producing products to the desired weight. Achieving zero waste and maximising yield should be joint objectives.

Other operational considerations that will feed into the decision you make when choosing a portion cutter include:

- What are your throughput requirements? Can the machine operate at a fast-enough speed?

- What about hygiene and cleanability? Does the portion cutter have an open structure design to make it easy to clean both on the inside and outside? Are the belts easy to remove for cleaning duties?

- Are there seasonal trends that will change the portion cutting requirements of your line?

- Is the machine easy to use and programme?

- Does the portion cutter offer real-time monitoring capabilities, and does it collect data to feed into your systems and produce reports?

Getting Expert Advice

As you can see, there is a lot to consider when choosing the right meat portion cutter. Help is available, however, as we have experts on our team who can provide you with comprehensive advice once they have a full understanding of your requirements. Visit our contact page to get in touch.