Technology Focus: Multihead Weighers

Multihead weighers enable highly accurate, fast, and reliable weighing of food and non-food products. At SF Engineering, our equipment partner Ishida is the world’s leading manufacturer of multihead weighers. This means we can provide food manufacturers with tailored solutions that enhance production line performance and deliver a fast return on investment.

The range of solutions that are available includes entry-level multihead weighers, mono-product options, and high-performance machines that operate at the cutting edge of food processing technologies. As a result, there are options available for straightforward lines up to the most challenging product and packaging conditions.

Leading the World in Multihead Weigher Technology for Over 50 Years

Last year, 2022, marked the 50th anniversary of Ishida’s multihead weighing technology. Today, Ishida multihead weighers are used by food manufacturers across all industry segments to improve productivity, increase automation, and reduce product giveaway.

Ishida was founded 130 years ago in Kyoto, Japan where it started manufacturing weighing scales. Its product range today includes food bag makers, fresh food weighers, checkweighers, X-ray inspection equipment, weigh price labellers, tray sealers, and, of course, multihead weighers.

The world’s first multihead weigher was introduced by Ishida to the food industry in 1972. It represented years of research and development and was designed to automatically weigh green peppers to produce fixed-weight packs. It was a significant technology breakthrough that reduced product giveaway by up to 15 percent.

Ishida introduced the second generation of multihead weighers in 1981, bringing the technology to Europe for the first time by unveiling the product range at Interpack in Düsseldorf, Germany. This was also the first time Ishida described the machines as Computer Combination Weighers (CCWs).

By 1984, Ishida multihead weighers were being used on every continent except Antarctica, and they were becoming more advanced.

New models and technology innovations were introduced over the following years and decades, culminating in the launch of the 11th generation Ishida multihead weigher range, the CCW-AS, in 2022. The CCW-AS further improves productivity while also being easier to clean and more energy efficient.

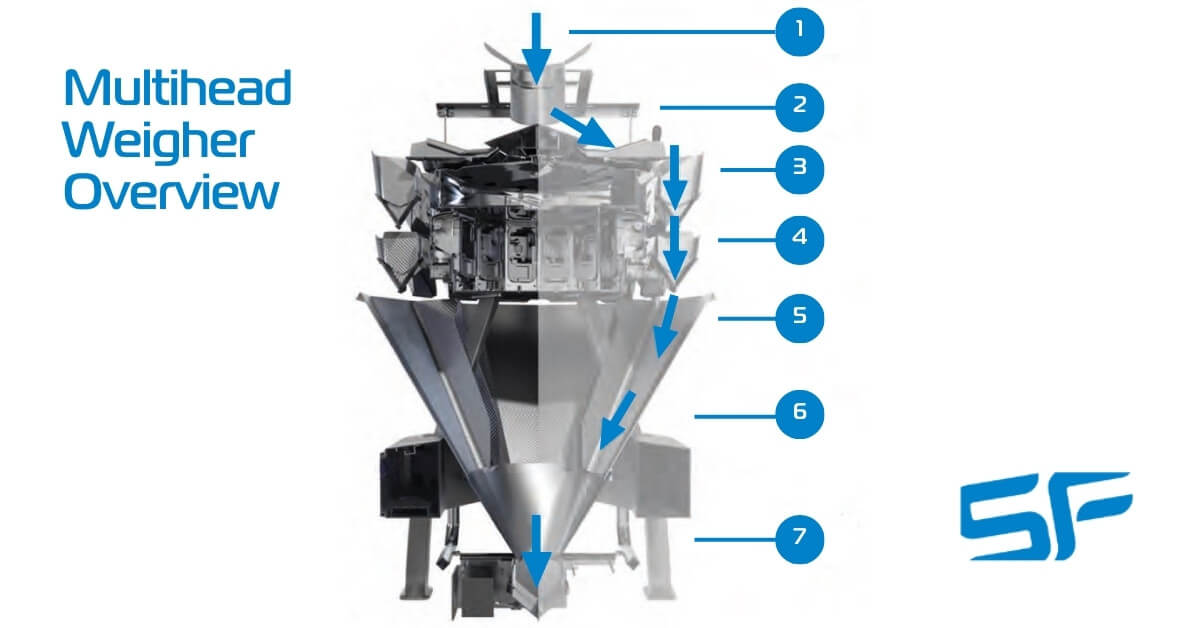

Overview of How Multihead Weighers Work

- The product flows into the multihead weigher’s inlet chute from the in-feed.

- The product is distributed via a dispersion table onto individually vibrating radial troughs.

- The product is then stabilised in the pool hoppers.

- The product then moves to the weigh hoppers where it is weighed.

- An optional booster hopper is often specified for higher speed or mixing applications.

- The system calculates the optimum combination of product which is then discharged through the discharge chute.

- The discharge of weighed product is timed to meet the distribution or packing solution.

Multihead Weigher Options

- Frozen protein weighers – options available for small, medium, and large protein pieces.

- Bakery and biscuit weighers – options for fragile, non-fragile, and frozen products.

- Cheese weighers – options for starched and unstarched grated cheese.

- Fresh produce weighers – ideal for bulky, free-flowing fruit and vegetables.

- Pet food weighers – ideal for bulk volume, large target weight, medium and large piece products.

- Salad weighers – options for small and large leaves as well as small and large target weights.

- Frozen vegetable weighers – options for all types of vegetables plus French fries, croquettes, rice, and more.

- Confectionery weighers – options for small and medium target weights of non-fragile and free-flowing products as well as sticky products.

- Dried fruit and nut weighers – options for small and medium target weights.

- Cereal weighers – options for small target weights of grains and pre-mixed cereals.

- Screwfeed weighers – multihead weigher options for fresh and marinated meat and poultry as well as fresh fish and seafood.

Benefits of Multihead Weighers for Your Food Production Facility

- Reduced product giveaway through highly accurate weighing

- Enables high-speed weighing

- Improved product quality

- Improved product handling with reduced damaged product losses

- Hygienic and easy to clean with minimised cleaning downtime

- Increased automation with minimal operator requirement

- Energy-efficient technologies

- Easy to operate with minimal operator training requirements

- Fast return on investment typically measured in months

Multihead Weigher Solutions for Your Production Lines

SF Engineering has extensive experience providing multihead weigher solutions both as part of new integrated weighing and packing lines or interfaced with the existing equipment on your line. To discuss the multihead weigher options that will help achieve your objectives and overcome current production challenges, please contact us today.