Conveyors & Platforms

Delivering reliable conveying solutions across the food industry

Conveyors To Keep Your Production Line Running Smoothly

Whether you are looking for a stand-alone conveyor, line upgrade, or a complete turnkey system, SF Engineering has the knowledge and experience to handle it.

With almost 40 years’ experience, our team of experts create the ideal solution for your conveying challenges.

Our innovative approach has enabled us to deliver successful conveyor systems to a wide range of customers across the red meat, fish, poultry, pet food, convenience, dairy, bakery, fruit & veg sectors, snack and confectionery sectors.

As a result of this, we have built a reputation within the industry for improving process flows in food processing factories around the world with our conveyor solutions.

Conveying solutions built from experience

Reliable & efficient

We design, build and install precision-engineered, highly efficient conveyor systems that withstand the rigorous demands of the food industry. All components have been proven to last in a 24/7 production environment.

Customisable

SF conveyors can be used as a stand-alone system or integrated into a continuous feed solution to suit multiple upstream or downstream processes. We can include variable speed or sensor controlled conveyors to suit your site requirements.

Reduced cleaning times

For high-care areas where hygiene is paramount, our open chassis, tubular conveyors help you cut down cleaning times by up to 40% due to our quick-release hinged side guards which makes sanitary access quick and easy.

High-quality components

All of our conveyors are manufactured from 304 grade stainless steel. We use food-grade, Intralox belting and run each conveyor with energy-efficient Lenze motors, resulting in a superior, cost-efficient solution. We also use fewer component parts in our solutions to ensure audit times are reduced for our customers.

Benefits of a conveyor designed by SF

Modular design, custom-built conveyors for each application

Save time and money with reduced clean down times

Purpose-built with strict food industry hygiene in mind

Fewer component parts which reduces audit times

Low cost of ownership

Robust and durable conveyors

Reliable and efficient conveyors

Easy to maintain conveyors

Built to suit your unique site requirements

With in-house Design, Mechanical, Electrical, Control and Project Engineers, we can guide you through the entire project from initial concept through to design, manufacture, installation and commissioning.

Whether it is a single piece of equipment or a full factory, we will ensure that all of the equipment is installed to schedule and will function to expectations.

These are examples of just some of the conveyors that we manufacture. If you can’t find what you need, please contact us with your requirements.

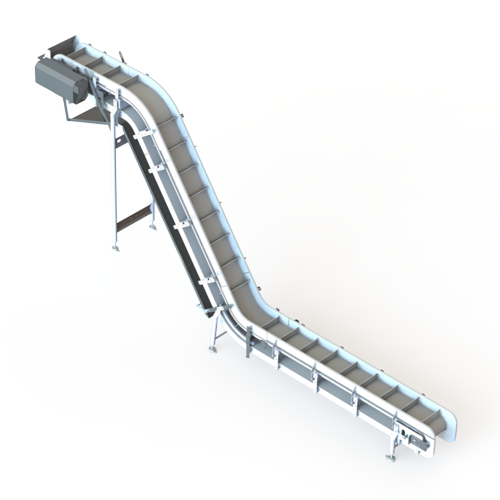

Elevator Conveyors

More Information on Elevator Conveyors

The SF Elevator Conveyor range enables high capacity transportation of products from one area to another. Designed to raise or lower your products in areas where there is limited space. Configured to suit your line, our conveyor solutions will transfer, lift vertically, convey long distances, and even decline in a controlled manner.

Available in a variety of belt styles, sizes, side guards, and with options to suit your application and to reduce product damage and spillage.

When used to feed a Multihead Weigher, the elevator is synchronised with the Multihead to ensure that the product feed is consistent and accurate weighments can be achieved. This smooth running elevator prevents any vibrations being transferred to the weigher.

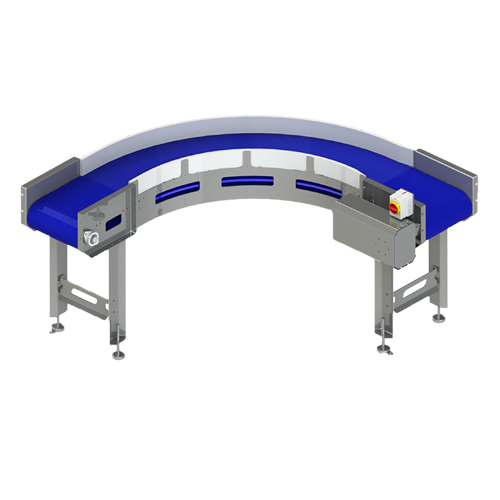

Conveyors

More Information on the SF Conveyor Range

The SF conveyor range is designed to be both hygienic and robust and have been proven to withstand the harsh environment of a food manufacturing factory, especially that of a red meat, poultry, or fish processing plant.

All the conveyors are modular in construction so that if a production line needs to be changed to meet a customer’s requirements, it can be done with minimal disruption and cost.

Belt lifters allow cleaning staff greater access to the conveyor chassis during washdown. This contributes to the overall reduction in washdown time and water consumption during the end of shift washdown process.

The modular belt design affords easy to access replacement parts, enabling the maintenance staff to easily complete scheduled maintenance, preventing costly production downtime.

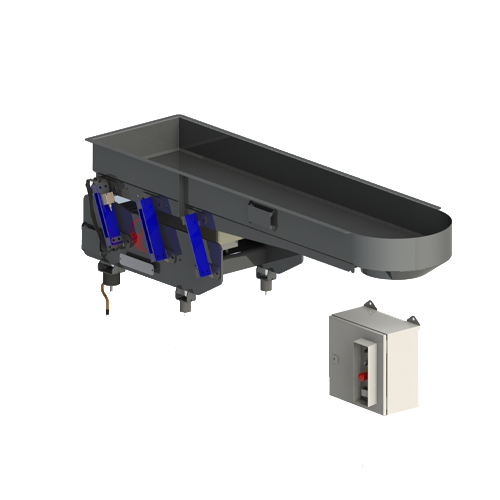

Vibratory Feed Conveyors

More Information on Vibratory Feed Conveyors

Vibratory Feed conveyors presents your product to the next piece of processing equipment. This maximizes yield and improves the performance of the downstream equipment.

The SF range of feed conveyors can modulate flow into the next piece of processing equipment with flexible conveying speeds and accurate feeding control. It provides a quiet conveying solution and a low operating cost.

Screw Feed Conveyors

More Information on Screw Feed Conveyors

Accurate blending and mixing is a basic requirement for the manufacture of high-quality products in the food industries.

The SF screw conveyor is designed with an intake hopper to allow a 200 litre euro bin of product to be stored in the hopper.

The hopper can also be fed from a production line and a product depth sensor is used to ensure the hopper does not overfill.

When the production line is started the screw turns and the product is metered out at a pace to suit production requirements.

Chain & Peg Conveyors

More Information on SF Chain and Peg Conveyors

The SF chain and peg conveyor is used to index and deliver trays into a filling station correctly where the product can be deposited from a distribution system into trays.

They can be manufactured to suit a unique style of container, or with our adjustable conveyor system, can be made to suit any number of different packaging types.

Sensors are fitted to ensure a tray is in place when it is being filled and also to ensure that the tray is in the correct filing location.

A tray denester can be used to drop empty trays. Alternatively, they can be placed manually on the chain and peg.

Roller Conveyors

More Information on Roller Conveyors

The Roller Conveyor is designed to transport and accumulate packed product where a buffer is required due to the production process.

Because it is manufactured to be both hygienic and robust, it suits the harsh environment of a typical production floor, making it ideal for use at the end of a packing line.

The option for stainless steel rollers allows the conveyors to be used for such applications as dairy factories, whereas PVC rollers are suitable for boxes, crates and packed products.

ARB Conveyors

More Information on ARB Conveyors

ARB for alignment

The ARB Alignment conveyor accurately aligns boxes, cases, cartons and shrink wrapped packages of all sizes. The conveyor gently drives a stream of randomly introduced items to one side, uniformly squaring them to one side against a guard rail.

Benefits of the ARB Alignment Conveyor:

- 40% smaller footprint than traditional skewer roller technology

- Guaranteed justification even after stop starts.

- Ensures precise spacing between products

Ideal for use before: Scanning, Labelling, Packing, Palletising etc

ARB for case turning

Available as ‘touchless’ turning for delicate products in high speed applications or gentle ‘Bump’ turning at lower operating speeds.

Products can be turned selectively or non-selectively and then precisely orientated and aligned. Enabling accurate product transfers to down line processes on a single conveyor.

These conveyors are also known as case rotators and orientation conveyors.

ARB for singulation

The ARB Singulation conveyor moves a group of side-by-side products into edge-aligned single file for down stream processes.

Benefits of this system:

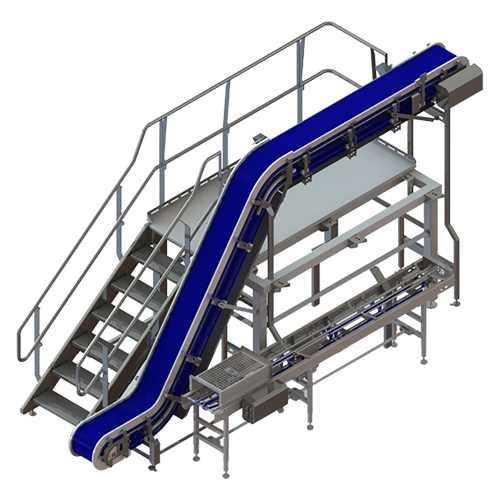

SF Platforms – Purpose Built To Suit Location & Application

SF Engineering platforms for the food industry are designed to be both hygienic and robust making them suitable for the harsh environment of any typical food processing factory.

They are typically designed to support the Ishida range of Multihead Weighers, allowing operators access to the product feed location for maintenance and cleaning.

Our platforms are designed to reduce vibrations through the Multihead Weigher, which improves the accuracy of the weigher and therefore reduces product giveaway.

Investing in the correct specification platform is essential when installing high-speed accurate weighing lines. This ensures your production lines achieve the maximum efficiencies and throughput whilst maintaining low product give-away.

Robust and easy to clean

We manufacture a range of different solutions, built to suit each application and requirement.

These are examples of just some of the platforms that we manufacture. If you can’t find what you need, please contact us with your requirements.

Multihead Weigher (CCW) Platform

More Information on Multihead Weigher Platform

The Multihead Support and Access Gantry is designed to support Multihead Weighers, allowing operator access to the product feed location for maintenance and cleaning on the Multihead Weigher.

The platform is designed to reduce vibrations through the Multihead Weigher, which improves the accuracy of the weigher and therefore reduces product give-away.

Fresh Food Weigher Platform

More Information on Fresh Food Weigher Platform

The Fresh Food Weigher (FFW) Platform is designed to support the Ishida range of Fresh Food Weighers and to allow operators access to the product feed locations on the FFW.

The platform is designed to reduce vibrations through the FFW which improves the accuracy of the FFW and therefore reduces the product giveaway. By installing a superior weigher on an inferior platform, the competitive advantage gained can be wiped out.

Multihead Support Frame

More Information on Multihead Support Frame

The Multihead Support Frame is used below a platform when vibrator feeders are positioned on the main platform. This guarantees the Multihead is isolated from vibrations which may cause a reduction in the accuracy of the weigher.

The Multihead Support Frame can be incorporated into layouts in conjunction with access gantries to provide a cost-effective solution to the weigher support and weigher access requirements.

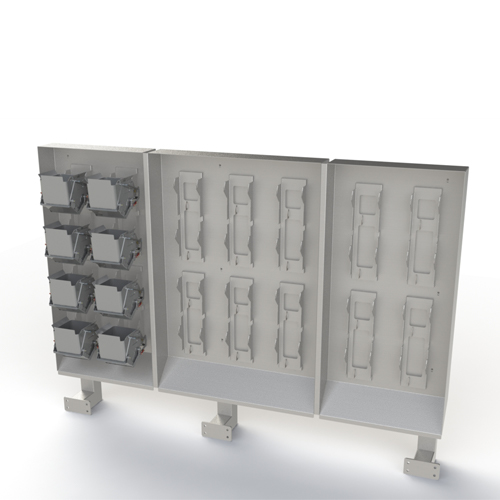

Wash Walls

More Information On Wash Walls

Our Washwalls are specifically used to mount the Multihead Weigher hoppers during cleaning.

Easily mounted to the side of the platform and designed to suit your multihead weigher, our washwalls give you a hygienic mounting solution, which is perfectly positioned to reduce labour time.

The walls are manufactured with an angled area to the bottom to ensure run-off water is held within the platform area.