Batching & Grading

Weighing & batching solutions for fresh fish, meat & poultry

Smart, flexible solutions for food grading applications

SF offers a range of batchers & graders to integrate multiple steps of the production line, to provide a total solution that ensures your raw product is weighed, divided and packaged correctly.

With the growing demand for ready meals and the requirement for food to be packed in a presentable way, we offer customised solutions for a wide range of batching and grading applications.

Our state-of-the-art technology creates highly advanced accurate and fast grading solutions for whole product, portioned product, fresh or frozen. We offer a full range of batchers and graders to meet all requirements.

Benefits of an SF grading solution

Grading with count or minimum weight

Batching to multiple target weights

Optimum weighing and batching combinations

Fast, accurate weighing of every piece

Reduced giveaway

Hygienic design and simple to clean batchers & graders

Modular, design to suit any application

Easy operation

Compact graders to customised grading solutions

Compact Grading

More Information on compact grading for small vulnerable products

The Compact Grader has been specially designed for the weighing and grading of small vulnerable products such as fish, poultry and meat. This efficient system is designed with infeed, weigher and outfeed in one simple and robust solution and the intelligent batching software can grade to size and number. There are various batching and other outfeed possibilities, from 2 to 8 stations, combined left/right or inline and by size.

Because grading small vulnerable products at high speeds requires a gentle approach, the Compact Grader has been designed to gently pull the product off the belt instead of propelling it. This reduces the risk of unnecessary product damage, rejected items, or consumer complaints.

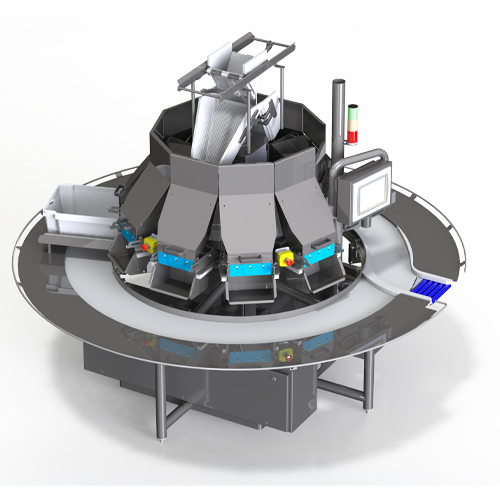

Rotobatcher

More Information on the SF Rotobatcher

The SF Rotobatcher combines the accurate weighing of fresh meat and poultry with manual packing to optimise their arrangement and presentation in trays.

The Rotobatcher has been developed for sticky meat and poultry products which cannot be easily moved by feeder vibration, or for when manual product feeding is not economically viable.

Your product is weighed automatically on our proven screwfeeder weigher and each accurately-weighed portion is then dispatched to one of the packing stations on the batching table, where an operator transfers it to a tray, styles it and places the tray on an ‘out’ belt for sealing, labelling and quality control.

The station automatically informs the system once the filled and styled tray has left, triggering the sending of another weighed item to be packed.

The Rotobatcher incorporates a user-friendly control panel, which allows the performance of each operator and each shift to be monitored.

An easy-clean design meets the stringent hygiene demands of the meat and poultry industry.

Weigh Batcher

More Information on Weigh Batchers

The SF Weigh Batcher offers perfectly styled trays of fresh meat and poultry with an efficiency, speed and accuracy unattainable with older methods such as hand packing.

It combines an Ishida screwfeeder multihead weigher, capable of moving the stickiest products, with rapid, ‘intelligent’ distribution to operators based in an ergonomically sound, compact workspace.

Each highly accurate weighment is conveyed to a workstation where it falls onto a holding gate. When the operator is ready, the weighment is released into a presentation tray. The operator then empties this into the final tray, styles it, and places it on an outbound belt for sealing, labelling and testing.

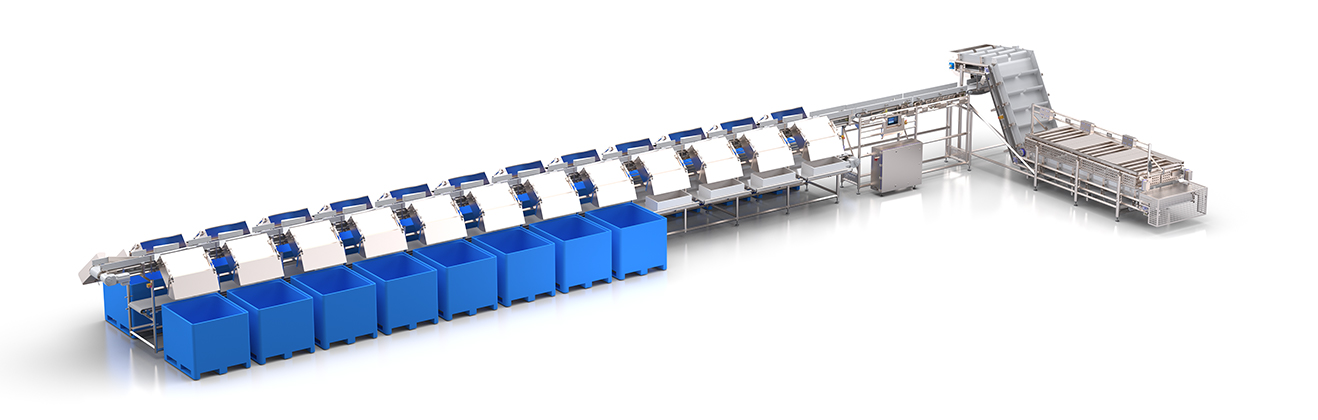

Customised Grading Solutions

More Information on Customised Grading Solutions

SF Engineering customised grading solutions offer vast flexibility, particularly in the wide choice of bin and outfeed arrangements available. The high degree of modularity means systems can be rapidly configured to meet the work requirements of the moment.

There are many benefits to reap that will make your grading tasks simpler, safer and more accurate.

- Modular separator allows you to add to or downsize your workstations as needed

- Batching technology accurately predicts pieces in advance, ensuring best possible selection

- Available in multiple configurations and sizes to suit most process requirements