Industrial Washers & Dryers

Efficient cleaning systems that save valuable labour & utility costs

Industrial Washers & Dryers Designed For The Food Industry

When it comes to cleaning, there are only two things that are important: high hygiene and low costs.

Our range of industrial washing solutions clean a range of products, including pallets, crates, trolleys, forms, trays or any kind of utensil, whatever the level or type of pollution.

These powerful, low-maintenance industrial washing solutions will help you save valuable labour and utility costs, whilst maintaining the highest level of hygiene.

From stand-alone units to fully integrated, automatic industrial washing and drying solutions

Benefits of SF Industrial Washers

High cost savings due to a reduction in labour requirements and water usage

Pivoting clip-nozzles are easy to adjust and offer exceptional coverage

Each system is low investment with high efficiency

Customisable depending on requirement and pollution level

Easy to use machines – no training required

Fully integrated or standalone solutions

Long-life stainless steel pumps

Low maintenance costs

Cost-saving industrial washing solutions for every pollution level

The food industry requires extremely high levels of hygiene and each industry sector presents its own challenges.

From the persistent fouling caused by smoke, fish slime and scales in the fish industry to the dried meat, blood, fat and foaming of the meat industry. You can be assured that each of our industrial washers is built to suit your exact pollution requirements.

If you need further assistance on SF Engineering’s industrial washers and dryers, please contact our team in Ireland or the UK.

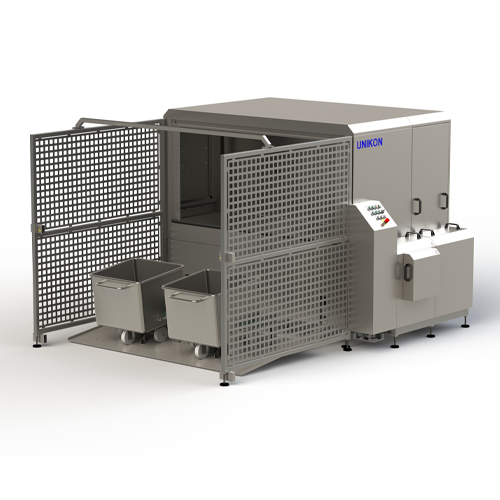

Crate Washers

More Information on Crate Washers

The UNIKON crate washer is modular in design making it easy to configure to your exact requirements. It has 3 main modules; pre-wash, main wash and blower module. Each is available in different sizes. This makes it easy and quick to build to the combination system that you require.

Even in a later stage when the machine is already in operation, it is possible to add modules to increase capacity, wash result or drying efficiency.

The crate washers use less water and energy, making them extremely efficient and reducing their operational costs.

In the wash section all contamination is removed. The water in this section is continuously filtered to assure good wash quality. The crates are rinsed with clean water. This water is then re-used for washing, ensuring lower water usage throughout. Lowering water consumption has an effect on chemical and heating power usage.

Optional pre-wash or drying sections can be added according to tailored requirements.

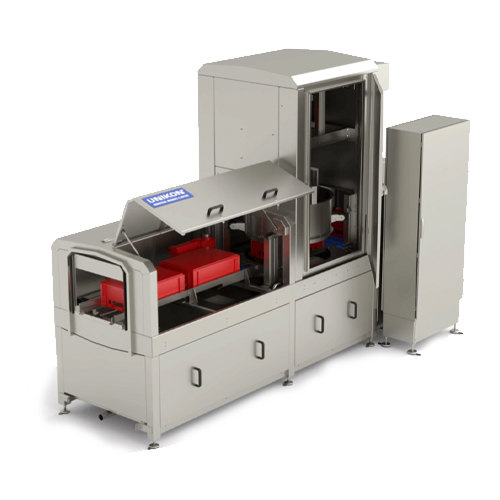

Tunnel Washers

More Information on Tunnel Washers

Our tunnel washers are suitable for a wide range and variety of manufacturing, packaging and transport equipment, from pallets and containers to chocolate moulds and cheese forms.

Each component passes through the front of the washing machines to the back and comes out clean. Large and small products, standard products or more varied products, the unique pivoting washing system removes even the toughest soiling.

We can provide the optimum washing and logistical solution for your products to match the capacity, from one to thousands of pieces per hour.

Pallet / Divider Washers

More Information on Pallet/Divider Washers

Pallets and dividers can be become very heavily polluted due to intensive use. Whether you clean just a couple of pallets a day or hundreds per hour, we can provide the perfect washing solution for your factory.

Our pallet / divider washing machines are fully tailored to your needs. From compact manually operated to fully automatic washing machines, we can customise to suit your production line.

Our standard pallet washer has a capacity of 50 to 100 pallets / dividers per hour. At high speed all contamination is removed. The low entry height makes these machines very user-friendly. The machine washes and cleans your dividers and pallets quickly and efficiently.

Trolley Washers

More Information on Trolley Washers

Regardless of the type of trolley you use, you can clean them in a UNIKON trolley washer. Using advanced cleaning techniques, trolleys are washed quickly and efficiently on all sides.

Supplied with a moving wash frame that is fitted with nozzles on four sides, washing time and washing power can be matched to the required cleaning requirement. As a result, trolleys are cleaned thoroughly either at high speed in a hand operated washing machine or in a fully automated trolley washer.

Cabinet Washers

More Information on Cabinet Washers

Our cabinet washers clean everything, from transportation and packing equipment to production line components, equipment and utensils. If necessary, we can create your fully customized cabinet washer to your specific needs.

De-Boning Glove Washers

More Information on De-Boning Glove Washers

In recent years the market has called out for a deboning glove washing machine that is thorough and efficient. With the development of this patented washing machine by our partner UNIKON, we can now offer a solution to Ireland and the UK meat industry.

With a wash cycle of only 15 minutes (up to 50

- Both a visually and bacteriologically, clean result

- A substantial saving in labour costs

- Very low water consumption (only 0.4 L per glove)

- A wash cycle of only 15 minutes (up to 50

gloves per cycle) - Simple and easy operation

- Low maintenance costs

- Reuse of the washing water by utilizing a built-in filter system

- The possibility of drying

- The guarantee of continuity through the use of A-brand parts, which are available worldwide

Crate & Pallet Spinner

More Information on Spin Dryers

The Unikon Spin Dryer, also called centrifugal dryer, is a flexible, durable and innovative solution for drying various types of washed product carriers.

Drying pallets and crate before reuse is much more hygienic and ensures the food products are not affected by residual moisture.

Pallet Spinner

Is suitable for

- Plastic pallets

- Whole or half size pallets

- Other types of pallets

Spin Dyer

Is suitable for

- Crates like E1 & E2 & E3 or foldable crates

- Bread tins & baking trays

Achieve up to 90% Energy Saving

The efficiency of the UNIKON Spin Dryer results in an energy saving of up to 90% compared to air dryers. The Spin Dryer offers an amazing drying result of up to only a few grams of moisture per unit. The dryer can be an extension to your existing washing machine and is effortlessly integrated into your existing washing process.

Blowers & Dryers

More Information on Blowers & Dryers

In our industrial washing machines the components are cleaned using water. On occasions, these components need to be dry before re-entering the production process. You can do that with the addition of a drying system.

We provide our uniquely constructed drying systems with air knives that blow hot or cold air. These drying systems can be custom built to seamlessly connect to your industrial washing machine allowing full integration into your production process.

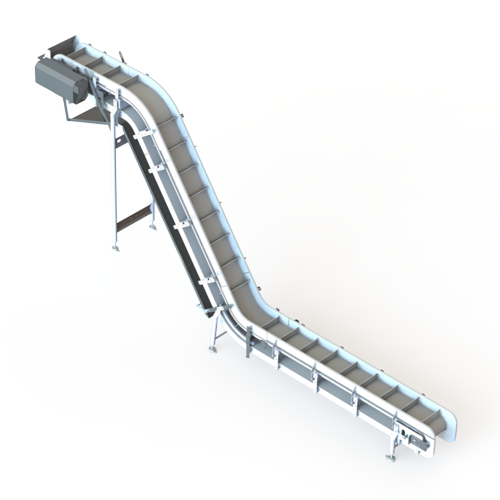

Fully Automated Logistic Washing Systems

More Information on Logistic Washing Systems

Our fully automated logistic washing systems have been designed to fully automate the washing process within a food production environment. The speed of the logistics system is linked to the capacity of your washing machine including systems such as de-palletizing or palletizing, stacking or de-stacking, feeding and disposal.

There is no manpower needed.