Checkweighers

Providing accurate verification of product weight & count

Customer Satisfaction Through Quality Control Checkweighers

Checkweighers are used to automatically check the weight of packaged foods, ensuring the weight of the packs is within specified limits.

This quality control check promotes customer satisfaction and helps you meet the strictest legislative requirements.

We are a preferred partner of Ishida, who is a world leader in checkweigher technology for the food industry.

We supply the full Ishida checkweigher range which is capable of handling various pack types, including bags, trays and cartons.

Benefits of an Ishida checkweigher

Checkweighers offer high accuracy

Rapid throughput

Hygienic open design of checkweighers

High reliability

Incorporates a high-performance load cell for faster stabilisation of weigh-signal

Robust design that protects the weighing mechanism against impact and heavy loads

User-friendly and intuitive display options which includes touch screen capability

Modular, space-saving design with integrated metal detectors and reject systems

DACS – To guarantee correct pack weights and control product integrity

All Ishida checkweighers can be equipped with multiple standard options to enhance performance and usability.

If you need further assistance, please contact our team in Ireland.

Performance Line - For retail compliance

More Information on Performance Line

The DACS-GN-S is the next-generation checkweigher, representing the very best iterations to date, designed to enhance and improve speed, precision, reliability and operational simplicity. The ideal weighing solution for a variety of product types – fresh, frozen, open, wrapped, boxed or multipacked.

A patented Ishida high-speed load cell feeds a GN generation processor to deliver impressively accurate weight determination. Typically for line speeds of up to 320ppm where full inspection is required.

The DACS-GN range is available in two model options for Dry (IP54) and Wet (IP65) production environments. With weighing capacities of up to 1.5kg and 6kg and a choice of reject options for product types and line speeds.

This next-generation checkweigher complies with all relevant European weights and measures legislation and directives, including WELMEC and OMIL, and has MID approval.

Contact SF Engineering Ireland for more information.

Excellence Line - For the majority of applications

More Information on Excellence Line

The ultimate performance from the DACS-G checkweigher series, Ishida’s DACS-G series culminates 40 years of experience in checkweigher design and manufacturing.

This range of advanced checkweighers offers high accuracy and a rapid throughput with outstandingly reliability, even under the harshest conditions. Each model offers two different weighing ranges, selectable at the touch of a button, enabling a very wide weight spectrum to be handled.

- Incorporates Ishida’s high-performance load cell for faster stabilisation of weigh-signal

- Robust design protects the weighing mechanism against impact and heavy loads

- Space-saving, open frame design with optional metal detector

- Two colour display options, touch screen for the easiest of operations of your checkweigher

- Compliant with European Measuring Instruments Directive (MID)

The DACS-G range is suitable for a vast majority of applications.

Contact SF Engineering Ireland for more information.

Advance Line - For speeds of up to 600 packs per minute

More Information on Advance Line

The DACS-GN-F is latest next-generation of checkweigher. Including enhancements to software, electronics and mechanical design to deliver improvements in weighing speed, accuracy, with intuitive operational simplicity.

The Advance range is used for high line speeds with no sacrifice of accuracy. Typically for line speeds of up to 480ppm where full inspection is required while delivering impressive accuracy, with a minimum graduation of 0.1g.

A solution to match your exact needs: From weigh table size to rejectors and software, a wide choice of options enables us to tailor each Advance-Line checkweigher to meet the exact requirements of your application and line configuration.

Built to withstand tough working conditions: Robustly constructed on a stainless-steel framework, Advance-Line checkweighers are engineered to deliver many years of service in the most demanding applications.

Easy to clean and maintain: The simplified, open design means that cleaning of the checkweigher and the floorspace beneath it can be carried out in minutes, helping keep downtime to a minimum.

Fully compliant: The Advance-Line checkweigher is approved in accordance with WELMEC and OMIL Directives.

Contact SF Engineering Ireland for more information.

Carton Line - Inspection of boxes / bags up to 60kg

More Information on Carton Line

Easily handles large items, so you don’t have to. The Carton-Line models ensure that the inspection process flows smoothly, handling weights from 150g all the way up to 60,000g and keeping heavy lifting by your staff to the minimum.

Impressive speed and accuracy: These checkweighers keep inspection moving at belt speeds of up to 55m/min and can detect a weight discrepancy as small as 1g, thanks to the patented Ishida high-speed load cell.

Configurable to your exact needs: A free-standing display unit makes integration into the line quick and easy, while line infeed and extension conveyors can be configured to suit your specific requirements. You can choose a roller or belt feed conveyor of either waterproof or dry construction.

A rich source of data: Data capture can take place via USB download or direct printout.

Simple set-up, operation and maintenance: The simplified, intuitive interface makes Carton-Line checkweighers easy to configure and operate.

Compliance built in: All Carton-Line checkweighers comply fully with European safety and weight directives.

Contact SF Engineering Ireland for more information.

IDCS Data Capture System - To reduce product give-away

More Information on IDCS Data Capture System

The IDCS collects data from every pack that has passed through your Ishida checkweigher and integrated metal detectors, generating dynamic, graphic displays and reports with a wide range of profitable uses.

The system provides all the information you need to reduce giveaway and downtime to increase efficiency (including Overall Equipment Efficiency, OEE), making a real and lasting contribution to your production line.

The capabilities of the system include live display of losses through overfilling, presented as pounds sterling or euros; presentation of incentive schemes to motivate shop floor staff as they interact with the device; data collection that can identify whether training or equipment adjustments are needed.

Contact SF Engineering Ireland for more information.

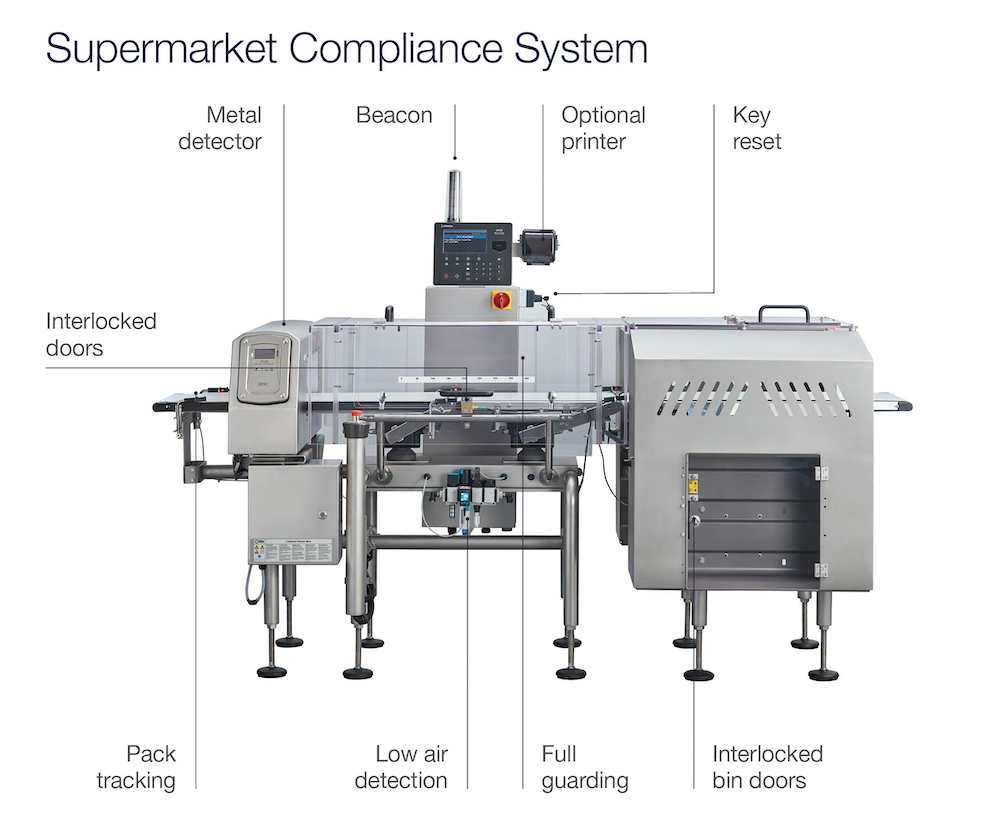

Combination Checkweigher and Metal Detection

More Information on Checkweigher and Metal Detection

When used in combination, an Ishida checkweigher and a CEIA metal detector achieves accurate high-speed package inspection of all ferrous and non-ferrous metal contaminants including stainless steel, as well as verification of current product weight or count.

This space-saving solution is completely customisable depending on your requirement and can handle a range of packaged, boxed or bagged products at real-time line speeds.

Contact SF Engineering Ireland for more information.